Description

| Unit Size | Net Weight |

| 840 gram | 2 lb |

| 3 kg | 7 lb |

| 6 kg | 14 lb |

Stonelith is a two-component polymer/mineral composite resin system - an extremely versatile material for casting, moulding, and laminating aesthetic, creative, and structural pieces.Stonelith can be moulded and shaped to produce a wide variety of 3D artistic creations, such as small crafts, design furniture, ornamental components and concept prototypes. Stonelith has the ability to capture intricate details.Upon blending, it produces a robust and adaptable substance that can be moulded or laminated into an array of designs, surpassing the applications of traditional compounds.

Key features:

Application Examples:

Stonelith does not contain VOCs and ammonia to provide you with a safer, quality material. Stonelith is easy to use due to its extended working time. Stonelith contains a nanoform additive which boosts the material's self-defoaming properties and enhances air release.

Safety and Precautions:

Stonelith is considered a safer option than epoxy resin, mainly due to the lack of skin sensitization and skin corrosion issues associated with epoxy. This water-based polymeric material is considered a non-hazardous liquid when used as instructed.We strongly encourage you to always wear a mask when working with the particulate matter (base) of the Stonelith. Inhaling dust for prolonged periods can lead to respiratory system irritation and other related issues. Please refer to the Safety Data Sheet for further information.It is also important to note that the reaction between the base and the polymer is exothermic (5"x 5" x 3" block made with Stonelith reaches a temperature of 52C within 2.5 hours after mixing and application stage). You should NEVER encase any parts of the body in Stonelith, as it can lead to burns and injuries.

Key features:

- Water-based polymer technology is safer for the environment than solvent-based alternatives

- Ammonia free

- Fire resistant

- Impact resistant

- Pigmentable with Stonelith Colourants to get a unique appearance

- Can mimic materials such as stone, concrete and wood. Compatible with epoxy resins once cured

- Resistant to UV rays

Application Examples:

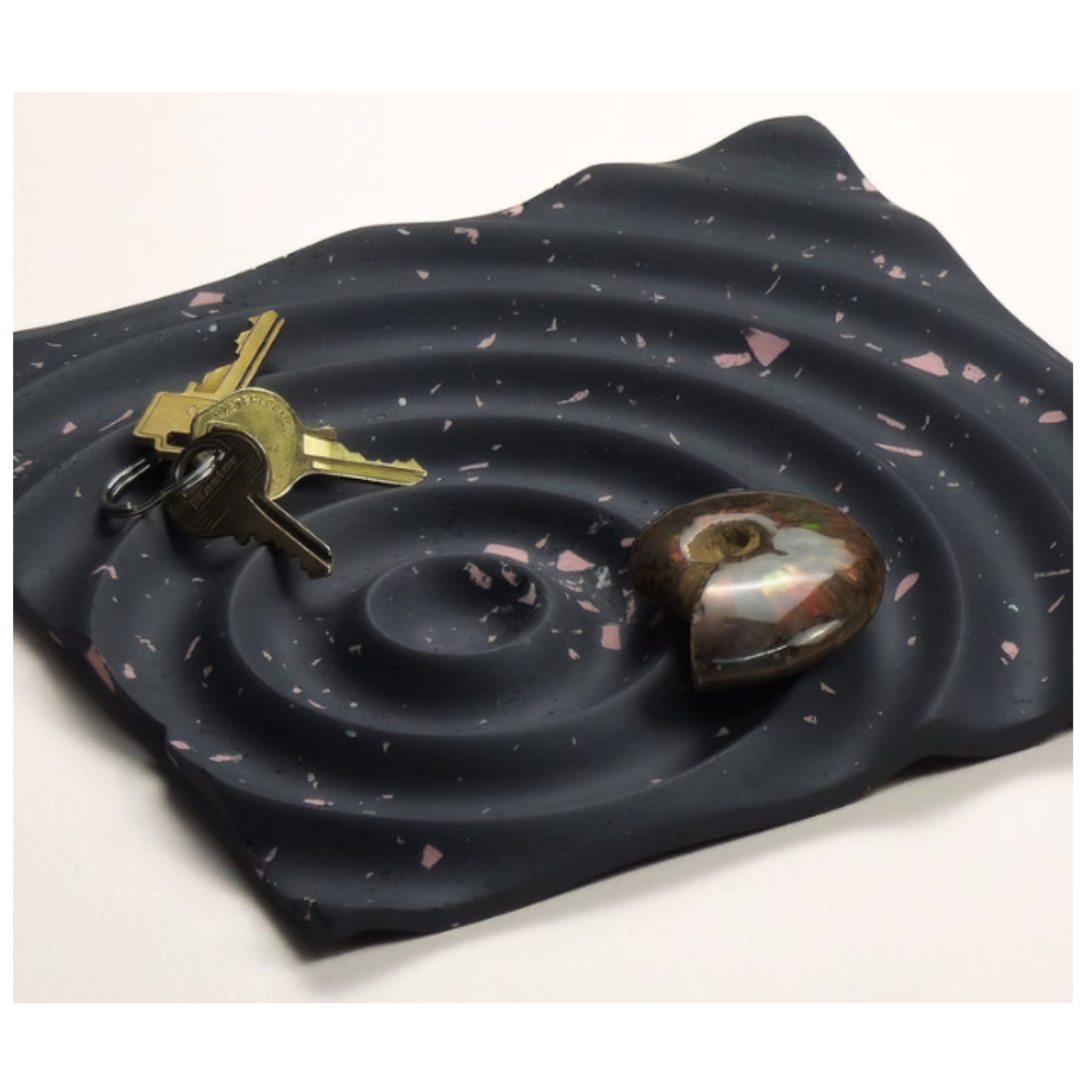

- Decorative crafts such as vases, trays, candle holders and others

- Terrazzo effect finish

- Designer furniture with complex shapes and unconventional configurations

- Complex geometry prototypes

- Expanded polystyrene (EPS) shell coating projects

- Lightweight construction applications such as composite lightweight structures

- Decorative wall panels

- Contoured canvas art

- Many others!

Stonelith does not contain VOCs and ammonia to provide you with a safer, quality material. Stonelith is easy to use due to its extended working time. Stonelith contains a nanoform additive which boosts the material's self-defoaming properties and enhances air release.

Safety and Precautions:

Stonelith is considered a safer option than epoxy resin, mainly due to the lack of skin sensitization and skin corrosion issues associated with epoxy. This water-based polymeric material is considered a non-hazardous liquid when used as instructed.We strongly encourage you to always wear a mask when working with the particulate matter (base) of the Stonelith. Inhaling dust for prolonged periods can lead to respiratory system irritation and other related issues. Please refer to the Safety Data Sheet for further information.It is also important to note that the reaction between the base and the polymer is exothermic (5"x 5" x 3" block made with Stonelith reaches a temperature of 52C within 2.5 hours after mixing and application stage). You should NEVER encase any parts of the body in Stonelith, as it can lead to burns and injuries.

Properties

- Mixing Ratio 2.5:1 by weight

- Yield : 840gram kit (52.7 cu.in.), 3kg kit (189 cu.in.), 6kg kit (378.4 cu.in.)

- Appearance (once mixed) white, opaque, low-viscosity liquid

- Appearance (once cured) white, opaque, hard material with a smooth, creamy texture

- Intended application : castings, coating, creative art, prototypes, structural pieces

- Working temperature 20C to 25C

- Mixed Viscosity 600-800 cps

- Working Time (hand-mixed 1.5 kg batch) 55 min

- Pot Life (hand-mixed 1.5 kg batch) 70 min

- Initial Set Time (hand-mixed 1.5 kg batch) 1 h 45 min

- Ready For Demolding Time 3 hours

- Recommended Demolding Time 3-5 hours after application

- Full Cure Time 72 to 96 hours

- Hardness 79 Shore D

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.