Description

| Unit Size | Net Weight |

| Pint Kit | 2 lb |

| Gallon Kit | 17 lb |

| Five Gallon Kit | 85 lb |

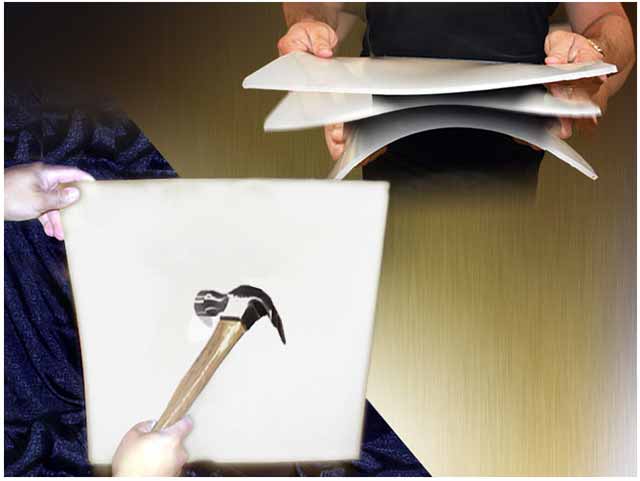

Smooth-Castª 45D is a new low-cost, mercury free semiÐrigid urethane casting resin that cures quickly to semi-rigid hardness that offers excellent impact resistance. Applications include: making high-impact resistance tools, prototypes, abrasion resistant parts, foundry patterns, roller facings, vibration pads, fast concrete stamping pads, etc.

Properties

Technical Properties

| Mix Ratio by Weight | 100A:93B |

| Mix Ratio by Volume | 1A:1B |

| Pot Life | 5 minutes |

| Cure Time | 30 minutes |

| Color | Translucent White |

| Shore Hardness | 45D |

| Mixed Viscosity | 250 cps |

| Shrinkage | 0.007 in./in. |

| Specific Volume | 25.2 cu. in./lb. |

| Specific Gravity | 1.10g/cc |

| Tensile Strength | 1,560 psi |

| Elongation @ Break | 100% |

These plastics are easy-to-use (mix ratio is 1A:1B by volume) and have low viscosities for minimal bubble entrapment. Vibrant colors are possible by adding SO-Strong and UVO Color tints. Smooth Cast 45D is virtually unbreakable and will really take a beating and offers exceptional abrasion resistance. Shore Hardness: 45D

How do I remove release agent from my cured urethane casting if I want to prime or paint the casting?

Removing a silicone-based release agent from your cured urethane casting is not easy. The most effective way is to sand blast or bead blast the surface of your casting. However, sand blasting removes a micro thin layer of the casting's surface. If not done properly, you can damage or remove fine detail. Soap Wipe or brush the casting with a soap that has high alkali content. Cascade brand dishwashing gel is highly alkaline and also contains baking soda, which is an advantage. Solvents Wipe or brush the casting with Acetone, Toluene, Isopropyl Alcohol or Mineral Spirits.

Important: follow all safety precautions when using flammable liquids. You can then prime and paint your casting.

How do I remove release agent from my cured urethane casting if I want to prime or paint the casting?

Removing a silicone-based release agent from your cured urethane casting is not easy. The most effective way is to sand blast or bead blast the surface of your casting. However, sand blasting removes a micro thin layer of the casting's surface. If not done properly, you can damage or remove fine detail. Soap Wipe or brush the casting with a soap that has high alkali content. Cascade brand dishwashing gel is highly alkaline and also contains baking soda, which is an advantage. Solvents Wipe or brush the casting with Acetone, Toluene, Isopropyl Alcohol or Mineral Spirits.

Important: follow all safety precautions when using flammable liquids. You can then prime and paint your casting.

Documentation

Special Order Items

PRODUCT ADVISORY:

The products listed below are currently SPECIAL ORDER items and require pre order.

Lead times may vary - For more information please contact our staff.

799217 - Smooth Cast 45D - Five Gallon Kit

The products listed below are currently SPECIAL ORDER items and require pre order.

Lead times may vary - For more information please contact our staff.

799217 - Smooth Cast 45D - Five Gallon Kit

Related Products

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.