Description

| Unit Size | Net Weight |

| Pint Kit | 1.9 lb |

| Gallon Kit | 15.4 lb |

| Five Gallon Kit | 77 lb |

Smooth-Cast 310 is a slow-setting urethane casting resin which has an ultra-low viscosity and yields castings that are bright white and virtually bubble free.

Properties

Technical Properties

| Mix Ratio by Weight | 100A:90B |

| Mix Ratio by Volume | 1A:1B |

| Pot Life | 20 minutes |

| Cure Time | 4 hours |

| Color | White |

| Shore Hardness | 70D |

| Mixed Viscosity | 80 cps |

| Shrinkage | 0.0065 in./in. |

| Specific Volume | 26.4 cu. in./lb. |

| Specific Gravity | 1.05g/cc |

| Tensile Strength | 3,000 psi |

| Elongation @ Break | 7.5% |

| Compressive Modulus | 44,900 psi |

| Tensile Modulus | 134,000 psi |

| Flexural Strength | 4,000 psi |

| Flexural Modulus | 118,000 psi |

| Compressive Strength | 3,800 psi |

| Heat Deflection Temp | 120¼F |

The Smooth-Cast 300 Series of liquid plastics are ultra-low viscosity casting resins that yield castings that are bright white and virtually bubble free. Vacuum degassing is not necessary. They offer the convenience of a one to one mix ratio (one part A to one part B by volume). The differences between them are pot life and demold time.

These resins readily accept fillers (such as URE-FIL 3 from Smooth-On) and can be pigmented (Smooth-Cast 325 accepts pigments better than the SC 300 series). Fully cured castings are tough, durable, machinable and paintable. They resist moisture and mild solvents.

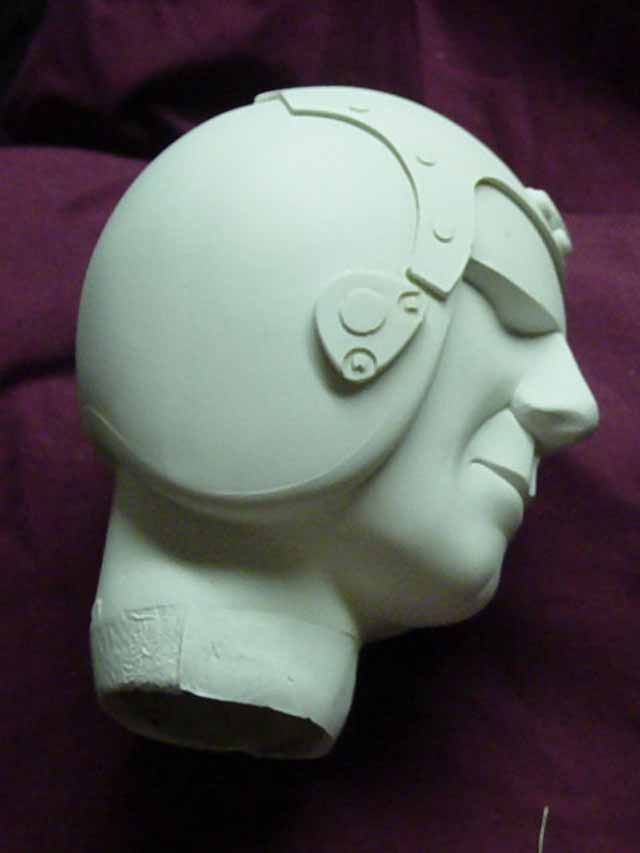

Applications for Smooth-Cast Liquid Plastics include reproducing small to medium size sculptures, cold cast bronze castings, making prototype models, special effect props and decorative jewelry. Those interested in making roto cast pieces should refer to the Smooth-Cast ROTO technical bulletin.

How do I remove release agent from my cured urethane casting if I want to prime or paint the casting?

Removing a silicone-based release agent from your cured urethane casting is not easy. The most effective way is to sand blast or bead blast the surface of your casting. However, sand blasting removes a micro thin layer of the castingÕs surface. If not done properly, you can damage or remove fine detail. Soap Wipe or brush the casting with a soap that has high alkali content. Cascade brand dishwashing gel is highly alkaline and also contains baking soda, which is an advantage. Solvents Wipe or brush the casting with Acetone, Toluene, Isopropyl Alcohol or Mineral Spirits.

Important: follow all safety precautions when using flammable liquids. You can then prime and paint your casting.

Documentation

Related Products

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.