Description

Casting Epoxy Museum Grade is a one-of-a-kind resin system formulated for clear, non-pigmented artwork, designer projects, glass-like laminating finishes and restorative works.

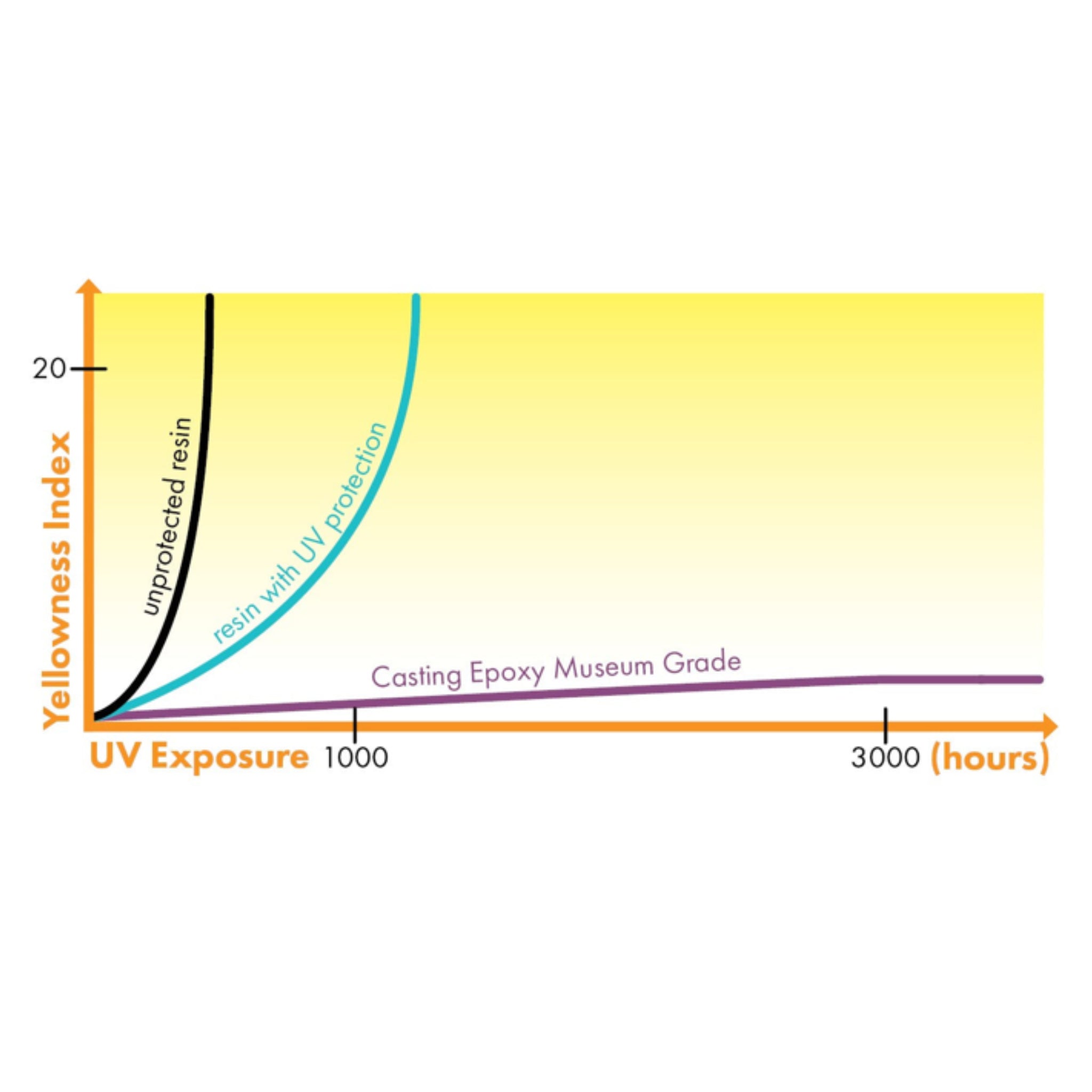

The key feature that makes this system "museum grade" is its anti-yellowing properties. Unlike regular epoxy resin types, Casting Epoxy Museum Grade is based on modified epoxy resin chemistry, avoiding the extreme susceptibility to UV rays, oxidation, and other processes that cause epoxy to yellow.

Another property of this resin that is not found elsewhere is its glass-like appearance. When light passes through the epoxy layer, it bends the same way as if it were to pass through the high-grade borosilicate glass. This physical property has a real-life benefit for end users, resin cast looks as close to glass as can be achieved for the liquid polymer type.

This epoxy is slow-curing, allowing casting layers up to 3" thick in one pour without overheating issues and the need for post-cure treatment. Depending on the thickness of the layer, resin takes 48-96 hours to solidify. This time can be significantly shortened if a heat chamber is used during the curing process.

Key features:

The key feature that makes this system "museum grade" is its anti-yellowing properties. Unlike regular epoxy resin types, Casting Epoxy Museum Grade is based on modified epoxy resin chemistry, avoiding the extreme susceptibility to UV rays, oxidation, and other processes that cause epoxy to yellow.

Another property of this resin that is not found elsewhere is its glass-like appearance. When light passes through the epoxy layer, it bends the same way as if it were to pass through the high-grade borosilicate glass. This physical property has a real-life benefit for end users, resin cast looks as close to glass as can be achieved for the liquid polymer type.

This epoxy is slow-curing, allowing casting layers up to 3" thick in one pour without overheating issues and the need for post-cure treatment. Depending on the thickness of the layer, resin takes 48-96 hours to solidify. This time can be significantly shortened if a heat chamber is used during the curing process.

Key features:

- Low-medium mixed viscosity for efficient air-release

- Extended working time

- Modified epoxy resin chemistry offers anti-yellowing properties that cannot be achieved with conventional UV protection

- Glass-like appearance due to a refractive index of the mixed resin similar to a borosilicate glass

- Accelerator-free controlled cure delivers the best results without harmful additives

Properties

- Mixing Ratio 2.7:1 by weight

- Appearance (mixed): clear, low-medium viscosity liquid

- Intended application : non-pigmented castings up to 3" thick with exceptional anti-yellowing properties

- Working temperature 22-27¡C

- Mixed viscosity 800-1200 cps

- Working time (2.0" thick 2L pour) 8-10 hours

- Pot life (1.0" thick 2L pour) 16-24 hours

- Set to touch (1.0" thick 2L pour) 48-72 hours

- Ready for sanding 72-96 hours

- Hardness 78 Shore D

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.